Digital Transformation of Carton Clamp Inspections

- steveross76

- Jul 14, 2025

- 1 min read

Case Study: Digital Transformation of Carton Clamp Inspections at Samsung – Groveland, FL

Overview

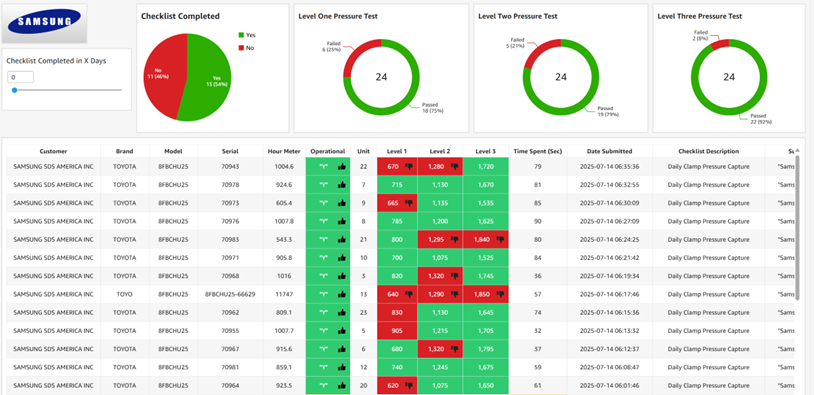

Samsung’s Groveland, Florida distribution facility needed a reliable, efficient way to validate that carton clamps were operating within manufacturer-specified parameters. Their existing system—based on paper checklists and Excel spreadsheets—was labor-intensive, error-prone, and lacked real-time oversight. To address this challenge, Samsung partnered with HiveQR to deploy a Daily Carton Clamp Digital Inspection Mobile App, transforming their inspection process into a seamless, data-driven workflow.

Challenges

Manual inspection processes relying on paper and spreadsheets.

Lack of real-time visibility for supervisors into clamp performance.

Difficulty identifying non-compliance or trends before issues occurred.

Increased administrative overhead to compile, store, and review inspection records.

HiveQR Solution

HiveQR implemented a mobile app specifically tailored to:

Guide operators through a digitized daily inspection checklist.

Automatically capture and timestamp inspection results.

Flag out-of-spec equipment instantly for corrective action.

Deliver a real-time visual dashboard to supervisory staff.

Key Features

Mobile Accessibility: Easy-to-use interface for on-floor personnel using phones or tablets.

Automated Data Capture: Eliminates transcription errors from manual logs.

Pre-set Operational Specs: Ensures clamps meet validated thresholds daily.

Supervisor Dashboard: Centralized view of inspection compliance across shifts.

Results & Benefits

Reduced Administrative Burden: 100% elimination of paper forms and Excel-based tracking.

Improved Compliance: Real-time alerts allow immediate action when clamps deviate from specs.

Data Transparency: Supervisors can now access dashboards anytime, enabling proactive equipment management.

Process Consistency: Standardized inspection routines across operators and shifts.

Comments